Manifold Destiny

(You knew I was going to use that subject eventually, so stop groaning.)

Arriving in various UPS shipments this week are numerous assorted micro-irrigation fittings, a bunch of electronic valves, and a heck of a lot of PVC pipe fittings.

I ended up having to order pipe fittings from a mail order place, because while most hardware stores had some of what I want, none had all of what I wanted, and I really did not want to be trailing all over the place looking for six more elbows or whatever. The place I ordered from, PlumbingSupply.com, had almost everything but a couple of specialty swivel fittings that I ordered from Dripworks, which is where I got everything else apart from the lawn sprinklers. I think that the complicated nature of my shopping list after simplification illustrates why I was loathe to add driving to every hardware store in town after 60 1" PVC tees.

So what am I building with all this stuff? The world's most overcomplicated irrigation system, of course. I designed a system with sixteen zones, and then threw a few more in to be capped off for future need. I was going to buy a commercial timer system to manage it, but Noel looked at them and offered to build one for me to my specs, with more stations than I can possibly think of using, so I took him up on it. I was not relishing using the stupid interfaces on those controllers, let me tell you. Something I can program with a text configuration file or a simple web interface off the house server is perfect.

The controller is not yet built or even totally designed. That doesn't matter. First we need the plumbing.

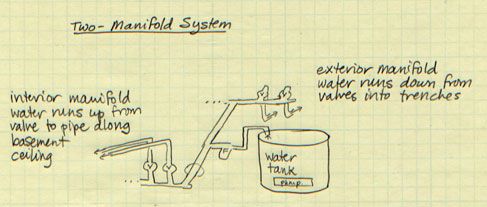

The manifold system has two sections, because of Noel's desire to avoid trenching. See, we looked into that trench drain stuff, and it's stupid expensive. $50 for four feet. I mean, I love me my modular design with easy access for modification, but that is not going to work AT ALL. So to minimize trenches but avoid the inevitable tripping over of the irrigation pipes, we're running a bunch of them along the ceiling of the basement to various outlet points around the house. And to minimize the holes in the shear walls that keep the house up when the ground moves, we're having a whole second manifold for those pipes inside the basement.

What on earth am I talking about?

Manifolds are where the irrigation plumbing gets divided up to go to valves and out to the irrigation zones. I want one outside, where it can run to the back yard zones, and another one inside, where we can route it to the fern walk, the side yard, and the front.

Like so:

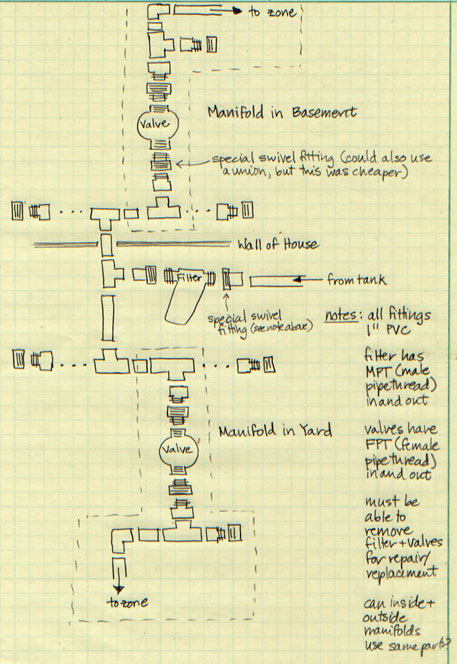

So I took that concept and diagrammed the pieces I would need to put this manifold together. I wanted to make the inside valve setups as much the same as the outside ones as possible, not for any good reason but to simplify parts and assembly. I figure that ten valve setups inside and ten outside will work with a lot of flexibility, and if I need more I can add them on later.

Also, to pre-emptively answer some questions, all the capped ends have three purposes: to allow expansion, to allow flushing of the system, and to leave room for installation of fertilizer injectors, if I want them at some point. Fertilizer injectors work with things like compost tea as well as synthetic fertilizers, so they are not entirely incompatible with my mostly organic approach to gardening.

These are all 1" PVC because that is the largest size I calculated I needed for my sprinkler size and pressure. I relied heavily on some books on irrigation from the library, water consumption information from the cooperative extension, and the information in Jess Stryker's Irrigation Tutorials. The size is highly situational, and if you're designing your own irrigation system I suggest you try out Jess's web page as a starter rather than assuming my system will work for you (especially because I have a really really tiny system and unusually low pressure, and my water is full of silt).

The supply coming out of the tank is going to be 1 1/4", so somewhere along the line I will be stepping down to 1" pipe, but that's not a big deal. While I have been reliably informed that it won't matter if the diameter of the pipe goes down then up around the valves, the concept bothers me because it is untidy plumbing. Fortunately, they make the valves and filters in a number of pipe diameters, so all was well.

And no, we do not yet have a tank or a pump. I have done the calculations to determine how much pump we need, and we decided on a 550-gallon tank last month, but I need to get around to ordering them.

Technorati Tags: automation, irrigation

posted by ayse on 06/06/06