Why We Caulk

This afternoon we went to remove the drywall that Stupid put up in the parlour. Noel had agreed that taking down at least one piece of drywall and giving me a better joint to plaster up was a good idea.

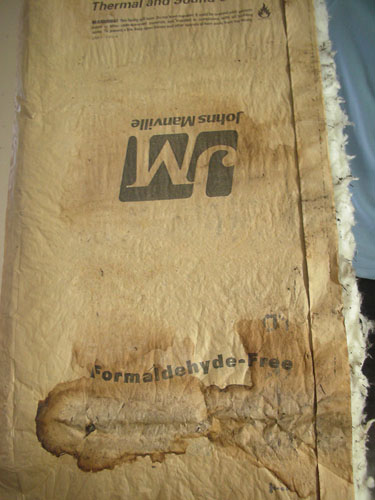

As you can see, the quality of the insulating the guy did was just as bad as his drywall. It's a mix of pieces of formerly encapsulated insulation (with encapsulation ripped, of course, so it wouldn't be effective), and paper-faced insulation.

We ended up taking down several pieces of drywall. You can see the nice, clean insulation on the side where we did the work, compared with the mess in the other bays. I guess some people think that what you don't see won't hurt you, right?

Except what you don't see, in this case, was wet insulation. Yup. All the stuff Stupid put in showed significant water damage. And mold. Yum. Thank goodness we did this now or it would have been much worse. We bagged it up to throw away.

Why did this happen to his work and not ours? Because behind our work we used silicone caulk and sealed up the back of the joints between each siding board. (You seal the back of a joint rather than the front so that even if the caulk fails, it still slows air penetration and keeps out the worst of wind-driven water.) We then put a rafter pan in each bay to leave an airspace that would allow wind-borne water to drip out of the wall, and then we stapled in encapsulated insulation that, when it needed trimming, had been re-encapsulated with tape. It was time-consuming, and a lot of work, but the payoff was obvious.

If we had left the mess Stupid put in our walls in place, the siding there would have rotted out within ten years. We'd also have a major black mold problem on our hands. This is why I don't trust contractors.

Under the insulation, we found lots of rubble from the fireplace (don't these people believe in vacuum cleaners?) and damp tarpaper on some (but not all) of the wall. It was like he knew there would be a problem with the siding leaking, but didn't care enough to do the job correctly.

The place where it looks like there's flour on the wall is where the insulation had stuck firmly to the tarpaper where the tar had gotten hot and melted. Generally, one does not put fiberglass right up against tar for a reason.

As you can see, the siding is pretty wet there where the insulation was holding the water against it (which is why you should not insulate a house with this kind of siding with plain fiberglass). We're going to let it dry out for a while; when it has a chance to breathe it tends to dry pretty nicely, though it's never been this thoroughly wet before.

Then we need to get a couple more sheets of drywall.

Technorati Tags: plaster, insulation, renovation horrors, water, weather

posted by ayse on 01/03/09